PEX-A and PEX-B are two types of cross-linked polyethylene piping, each with its unique features and benefits. Cross-linked polyethylene (PEX) piping comes in two main types: PEX-A and PEX-B, each with distinct advantages and applications.

Both offer high durability and flexibility, but PEX-A has superior burst resistance and can be repaired using expansion fittings, while PEX-B is more affordable and uses crimp or clamp fittings. Understanding the differences between PEX-A and PEX-B can help homeowners and contractors choose the best option for their specific plumbing needs.

We will explore the differences, applications, and pros and cons of both PEX-A and PEX-B piping, giving you the knowledge to make an informed decision.

Flow Chart Of Pex A And Pex B

Pex A vs Pex B: When comparing Pex A and Pex B, it is important to understand the key differences in materials and their applications in plumbing systems.

Overview: Pex A and Pex B both have their unique advantages and choosing the right one depends on various factors such as cost, durability, and installation method. Pex A offers superior flexibility and is ideal for use in long continuous runs, while Pex B is known for its affordability and resistance to chlorine.

Differences in materials: Pex A is cross-linked using the Engel method, resulting in a more uniform and durable pipe, whereas Pex B is cross-linked using the Silane method, which makes it more resistant to oxidative degradation.

Application in plumbing systems: Pex A is commonly used in residential and commercial plumbing applications due to its flexibility, making it easier to install in tight spaces, while Pex B is favored for its affordability and resistance to chlorine, making it suitable for potable water systems.

It’s essential to consider the specific requirements of your plumbing project before choosing between Pex A and Pex B to ensure optimal performance and longevity of the system.

Longevity And Durability

Both Pex A and Pex B have a good longevity, but Pex A has a slight edge in terms of durability and lifespan. Pex B is also durable and has a long service life, but it is less resistant to chemicals and environmental factors compared to Pex A. Pex A has a higher resistance to chemicals and environmental factors, making it more suitable for harsh conditions. This enhanced resistance also leads to lower impact on overall system maintenance, reducing the need for frequent repairs and replacements.

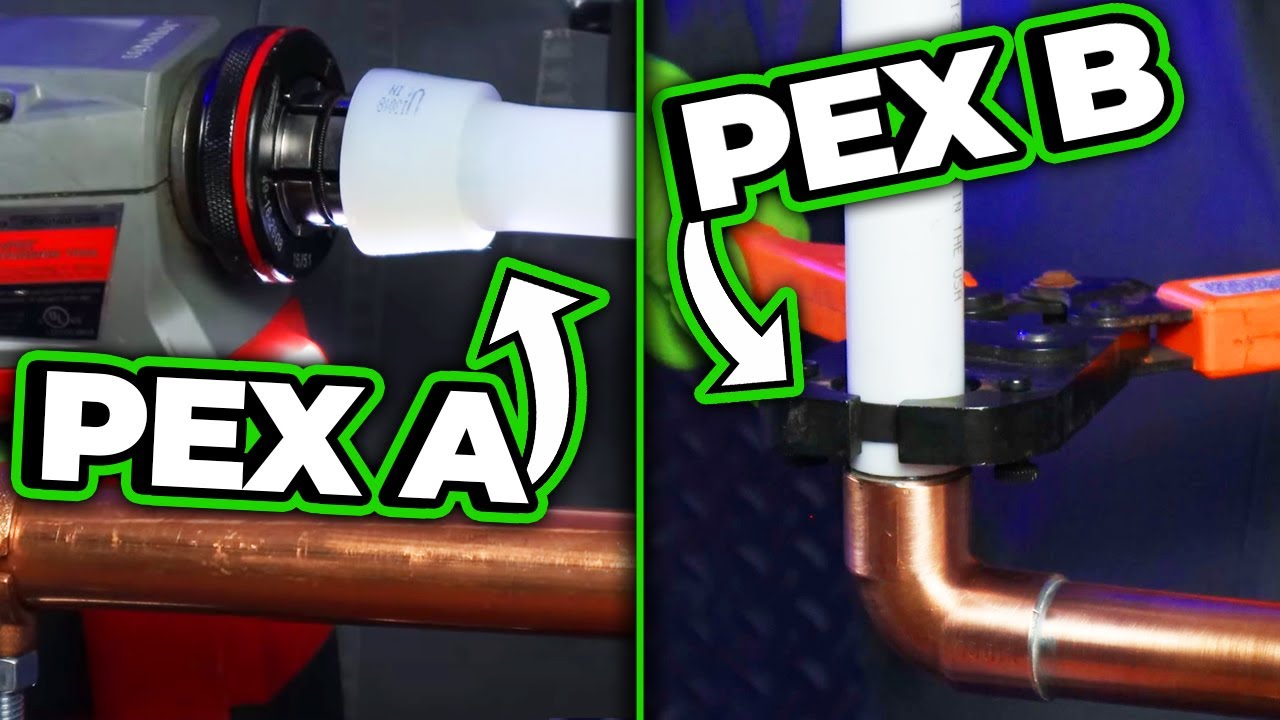

Fittings And Tools

Pex A vs Pex B fittings offer different features and benefits. Pex A fittings utilize expansion rings made from Pex or similar material, while Pex B fittings use metal cramp or clamp rings. The Pex A expansion technique involves using an expansion tool, while Pex B requires a crimping tool. In terms of tool requirements and costs, Pex A expansion tools are generally more costly compared to Pex B crimping tools. However, Pex A fittings are highly compatible with existing systems and are easy to install. Conversely, Pex B fittings may require additional care during installation due to the need for accurate sizing and shaping of the pipe. Therefore, when considering ease of installation and compatibility with existing systems, Pex A fittings have the advantage.

Price Consideration

When comparing Pex A and Pex B, price consideration is crucial. Pex A tends to be more cost-effective due to its flexibility and versatility, while Pex B may have lower initial costs but requires additional equipment. Understanding the long-term expenses and installation requirements is essential in making the best choice for your project.

| Cost analysis of Pex A and Pex B | Factors influencing the overall pricing |

| When comparing the long-term cost-effectiveness of Pex A and Pex B, it’s crucial to take into account the initial installation expenses, maintenance costs, and potential repairs. Moreover, system durability and energy efficiency need to be considered, as they impact the total cost of ownership over time. | The material quality, manufacturing process, and market demand play a significant role in determining the pricing of Pex A and Pex B. Additionally, regional variations in pricing, supplier relationships, and product availability can influence the overall cost of utilizing each type of Pex. |

Pros And Cons

Pex A Vs Pex B – When comparing Pex A and Pex B, it’s important to consider the advantages and limitations of each material and their impact on specific applications. Some advantages of Pex A include greater flexibility, resistance to kinking, and the ability to expand and contract without damage. On the other hand, Pex B offers a lower cost and can be crimped with a simple tool. However, it has reduced flexibility and is more prone to kinking. Both materials have their limitations, such as the need for specific fittings and potential water quality concerns. Understanding these differences is crucial in choosing the most suitable material for specific plumbing requirements.

Credit: m.youtube.com

Frequently Asked Questions For Pex A Vs Pex B

Should I Use Pex A Or Pex B?

PEX A offers better flexibility and resistance to burst pressure compared to PEX B. Consider your specific project needs.

How Do You Tell Pex A From B?

To differentiate PEX A from PEX B, check the labeling on the pipe – PEX A will say “PEX-A” and PEX B will say “PEX-B”. Additionally, inspect the fittings – PEX-B uses metal crimp or clamp rings, while PEX-A uses expansion rings made from PEX or a similar material.

Can You Switch Between Pex A And Pex B?

Yes, you can switch between PEX A and PEX B as plumbing codes allow mixing with suitable transitions.

Can I Use Crimp Rings On Pex A?

Yes, you can use crimp rings on PEX A, as it is compatible with expansion, crimp, and push-to-connect fittings.

Conclusion

After comparing PEX A and PEX B, it’s clear that both have their advantages and drawbacks. PEX A offers better flexibility and burst pressure resistance, while PEX B is more cost-effective. Ultimately, the choice between the two depends on individual needs and preferences, as well as specific project requirements.

When deciding which type of PEX to use, consider factors such as longevity, fittings, and price, as well as the unique pros and cons of each option. Consulting with a professional can also provide valuable insight.