To determine the amount of Teflon tape to use, wrap the tape around the male threads three to four times for a secure seal. This is the standard recommendation for most applications.

Teflon tape is used to create a tight seal between threaded pipe fittings, preventing leaks. The amount of Teflon tape needed depends on the size of the threads and the application. It’s essential to wrap the tape in the direction of the threads for a proper seal.

Following the industry standard, wrapping the tape around the male threads three to four times ensures a secure connection. Using the right amount of Teflon tape will help to prevent leaks and ensure a reliable seal for your plumbing or gas piping system.

How Much Teflon Tape To Use

When using Teflon tape, it is important to understand the basics of its application. The key factors that influence Teflon tape usage include the size and type of the pipe fittings, as well as the density of the Teflon tape. It’s recommended to use approximately 3 to 5 wraps of Teflon tape on the male threads, ensuring that the tape is wrapped in the direction of the threads. This usually provides an effective seal, preventing leaks and ensuring a secure connection. It’s essential to avoid over-tightening the fittings, as this can cause damage to the tape and compromise the seal. Additionally, inspecting the condition of the Teflon tape during routine maintenance is crucial to ensure its effectiveness, making any necessary replacements if the tape shows signs of wear or deterioration.

Teflon Tape Essentials

What is Teflon tape? Teflon tape, also known as plumber’s tape, is a thin, white tape used in plumbing for sealing pipe threads. It is made of polytetrafluoroethylene (PTFE), which provides a tight seal that prevents leaks in pipes and fittings.

The roles Teflon tape plays in sealing Teflon tape acts as a lubricant to help seal the joints and prevent leaks. The tape fills in the gaps between the threads, creating a tight seal that is essential for preventing leaks in plumbing connections.

Preparing For Application

When applying Teflon tape, it is important to use the right amount to ensure a proper seal. It is recommended to wrap the tape around the threads 3-5 times, maintaining a snug fit without over-tightening. This will help prevent leaks and ensure a secure connection.

Correct Application Techniques

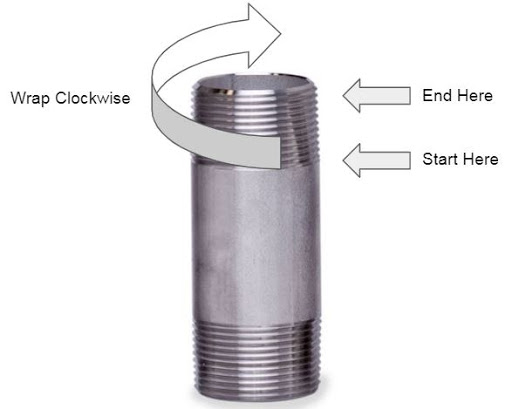

Teflon tape should be applied to the male threads of the fitting in a clockwise direction. It is important to wrap the tape tightly around the threads to ensure a secure seal. Adequate tension should be applied to the tape, but care should be taken not to over-tighten, as this can cause the tape to tear or shred. When wrapping the threads, it is vital to ensure that the tape is applied smoothly and evenly to prevent any gaps or areas of overlap. Avoiding mistakes such as wrapping the tape in the wrong direction or applying too much tension can help ensure a successful seal and reduce the risk of leaks. By following these step-by-step techniques and practicing good application habits, you can achieve an effective seal when using Teflon tape.

Adjusting Teflon Tape Use

When applying Teflon tape, it’s important to use the right amount. For most applications, a single layer of Teflon tape is sufficient to create a secure seal. However, when dealing with larger pipe sizes or when working with threaded fittings that have larger gaps, applying multiple layers may be necessary to ensure a leak-free connection.

Signs that you may be using too much Teflon tape include difficulty threading the connection, excessive tape visible on the threads, and the tape being pushed into the pipe when tightening. If you encounter any of these issues, consider reducing the amount of tape used to achieve the proper seal.

When working with different pipe sizes, it’s essential to adjust the amount of Teflon tape used accordingly. Larger pipes and fittings may require more tape to fill the gaps effectively, while smaller pipes may only need a single layer. By adjusting the amount of Teflon tape used based on the specific requirements of the job, you can ensure a reliable and secure connection.

Teflon Tape Alternatives

When considering thread sealant compounds, it’s important to weigh the pros and cons of using Teflon tape. While Teflon tape offers ease of use and cost-effectiveness, it may not be suitable for all applications. Some alternatives, like thread sealant compounds, provide a more robust seal and can handle higher pressures and temperatures. However, they may be more difficult to apply and require curing time. Additionally, alternatives may have a higher upfront cost but could offer long-term savings in certain scenarios. It’s crucial to evaluate the specific requirements of the project to determine the most suitable option for achieving a reliable and durable seal.

Best Practices

Industry recommendations for Teflon tape usage: When using Teflon tape, it is recommended to apply 3-4 wraps around the male threads, ensuring proper coverage without over-tightening. Tips for ensuring a leak-proof seal: Before application, ensure the threads are clean and free of debris to avoid tape dislodgement. After application, carefully tighten the joint to create a secure, leak-free seal. Maintaining the integrity of the seal over time: Regularly inspect the tape for wear or damage, replacing it as needed to maintain the effectiveness of the seal.

Troubleshooting Common Issues

Identifying and fixing leaks: When troubleshooting common issues with Teflon tape, it’s important to first identify any leaks in the fittings or connections. Once the leaks are located, they can be fixed by tightening the fittings or replacing damaged components.

When to remove and reapply Teflon tape: If you find that the existing Teflon tape is damaged, frayed, or not providing a proper seal, it should be removed and replaced with a fresh application of tape. Additionally, if the fittings are being reassembled, it’s recommended to remove the old tape and apply a new layer for a secure seal.

Safe disposal of used Teflon tape: Proper disposal of used Teflon tape is important to prevent environmental contamination. It should be securely wrapped and placed in the appropriate waste disposal container according to local regulations. This ensures that any residual tape is contained and disposed of responsibly.

Credit: www.rcworst.com

Frequently Asked Questions For How Much Teflon Tape To Use

How Much Teflon Tape Should I Use For Plumbing Connections?

For small pipe threads, apply 3-4 wraps of Teflon tape. Larger threads may require 8-10 wraps for a secure seal. It’s important to wrap the tape in the same direction as the thread to ensure it doesn’t unravel during installation.

What Is The Significance Of Using Teflon Tape?

Teflon tape acts as a lubricant to help thread components together smoothly and provides a reliable seal to prevent leaks. It also helps to prevent seizing or binding of threaded connections, making them easier to disassemble in the future.

Can I Re-use Teflon Tape?

Teflon tape is designed for single-use applications. Once the joint is disassembled, the tape loses its effectiveness and should be replaced. Using new tape with each connection ensures a proper seal and prevents the risk of leaks or faulty connections.

Conclusion

Using the right amount of Teflon tape is crucial for leak-free and secure sealing of pipe fittings. By following the recommended guidelines and understanding the proper application techniques, you can ensure a reliable and durable seal for your plumbing needs.

Mastering the Teflon tape application will save you time and money in the long run.