Compression fittings are easier to install and remove than solder fittings, which create a stronger, more permanent bond.

Compression and solder fittings are popular methods for joining pipes in plumbing. Compression fittings use a nut, ring, and fitting to create a seal, making them ideal for quick and temporary connections. They are user-friendly and do not require heat or specialized tools.

On the other hand, solder fittings involve melting solder to join pipes, resulting in a more durable and leak-resistant bond. This method is preferred for long-term installations but requires more skill and equipment. Both options have pros and cons, depending on the specific requirements of your plumbing project.

Compression Fittings

Plumbing projects often require choosing the proper method to join pipes. Two popular methods are compression fittings and soldering. Understanding the differences between these methods helps in making an informed decision. This guide focuses on compression fittings and their pros and cons.

What Are Compression Fittings?

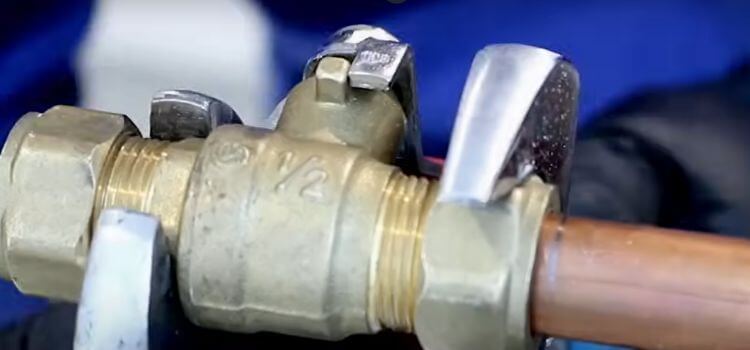

Compression fittings connect two pipes or a pipe to a fixture. They consist of three main parts: a nut, a ring (or ferrule), and a seat. The pipe is inserted into the fitting, and the nut is tightened. This action compresses the ring between the nut and the seat, creating a seal.

Compression fittings are popular due to their ease of use. They do not require any special tools or skills. Here are the main parts of a compression fitting:

- Nut: Tightens the fitting.

- Ring (Ferrule): Creates the seal.

- Seat: Holds the pipe in place.

These fittings are ideal for temporary or adjustable connections. Many DIY enthusiasts prefer them for small plumbing tasks. They work well with both metal and plastic pipes.

Advantages Of Compression Fittings

Compression fittings offer several advantages over other methods:

- Ease of Installation: No special tools are needed. A simple wrench can do the job.

- Quick Assembly: They take less time to install compared to soldering.

- Reusability: These fittings can be easily disconnected and reused.

- Versatility: Suitable for both metal and plastic pipes.

- Safety: No open flame is needed, reducing fire risks.

These benefits make compression fittings a popular choice for many home plumbing projects. They are handy for quick repairs and temporary setups.

Disadvantages Of Compression Fittings

Despite their many advantages, compression fittings also have some drawbacks:

- Potential for Leaks: If not installed correctly, they can leak.

- Limited to Low Pressure: Not suitable for high-pressure systems.

- Periodic Maintenance: They may require tightening over time.

- Bulkiness: They can be bulkier compared to soldered joints.

- Material Limitations: Not all materials are compatible with compression fittings.

Understanding these drawbacks helps in deciding if compression fittings are the right choice. They are excellent for specific applications but might only be suitable for some scenarios.

Soldering

Choosing between compression fittings and soldering is a common dilemma. Both methods are used to join pipes, and each has its own set of pros and cons. Let’s explore soldering in detail.

What Is Soldering?

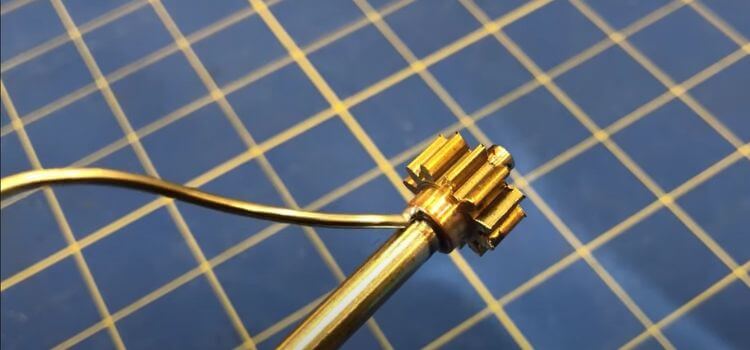

Soldering is a process of joining two or more metal items. It involves melting a filler metal, called solder, into the joint. The filler metal has a lower melting point than the workpieces. Soldering is used in plumbing, electronics, and metalwork.

The process involves heating the metals to be joined. A soldering iron or torch is used. The solder melts and flows into the joint. It then cools and solidifies, creating a strong bond.

Key points:

- Soldering uses a filler metal called solder.

- It joins metals by melting the solder into the joint.

- Commonly used in plumbing, electronics, and metalwork.

Advantages Of Soldering

Soldering has many benefits. It creates a strong, durable bond. The bond is also leak-proof. This is crucial in plumbing applications. Soldering is also very precise. It allows for intricate connections. This is especially important in electronics.

Main advantages:

- Creates a strong, durable bond.

- Results in leak-proof joints.

- Allows for precise, intricate connections.

Another advantage is its versatility. Soldering can join different types of metals. It is also relatively easy to learn, and anyone can master it with practice.

Disadvantages Of Soldering

Soldering has some drawbacks. It requires heat, which can be a safety hazard. If not careful, burns and fires are possible. Soldering also involves skill. It takes time and practice to do it well.

Main disadvantages:

- Requires heat, posing a safety hazard.

- Demands skill and practice.

- Time-consuming process.

Another issue is the need for proper ventilation. Fumes from solder can be harmful. This is especially true in enclosed spaces. Adequate safety measures are a must.

Comparison

Compression fittings and soldering are two popular methods for connecting pipes in plumbing. Each has its advantages and disadvantages. Understanding these differences is crucial for making the right choice for your project. This comparison will help you decide which method is best for your needs.

Installation Process

Compression fittings are known for their simple installation process. They do not require any special tools or skills. Here are the basic steps for installing a compression fitting:

- Cut the pipe to the desired length.

- Slide the compression nut onto the pipe.

- Place the compression ring (an olive) over the pipe.

- Insert the pipe into the fitting.

- Tighten the compression nut onto the fitting.

Soldering, on the other hand, requires more skill and special tools. The process involves:

- Cleaning the pipe and fitting.

- Applying flux to both the pipe and fitting.

- Heating the joint with a torch.

- Applying solder to the heated joint to create a seal.

Soldering takes longer and requires more precision. Mistakes can lead to leaks or weak joints. Compression fittings offer a quicker and more straightforward installation.

Leakage Potential

Leakage potential is a significant factor when choosing between compression fittings and soldering. Compression fittings rely on the tightness of the nut and ring to create a seal. If not tightened properly, they can leak. Over time, the seal can also weaken due to vibrations or temperature changes.

Soldered joints are more permanent and less likely to leak. Once the solder has cooled and hardened, it creates a strong bond. This bond is less susceptible to movement and temperature changes. For long-term reliability, soldered joints are often preferred.

Soldering provides a more secure connection when pipes are exposed to frequent movement or extreme temperatures. Compression fittings are easier to install but may require more frequent checks to ensure they remain leak-free.

Versatility

Versatility is another important consideration. Compression fittings can be used with various pipe materials, including copper, plastic, and stainless steel. This flexibility makes them suitable for many types of plumbing projects.

Soldering is typically limited to copper pipes. While copper is a common material in plumbing, there are better choices for some projects. This limitation can be a drawback when working with different materials.

Compression fittings also allow for easy disassembly and reassembly. This feature is helpful for temporary installations or when future modifications are expected. Soldered joints are permanent and require cutting the pipe to make changes.

Compression fittings offer a clear advantage for projects requiring flexibility and future adjustments.

Cost

Cost is an essential factor for many homeowners and contractors. Compression fittings are generally more expensive than the materials needed for soldering. The fittings can be pricier, and the cost can add up for large projects.

Soldering materials, such as solder and flux, are relatively inexpensive. However, the need for a torch and other tools can increase the initial investment. The overall cost can be lower for those already equipped with soldering tools.

Compression fittings can save money on labor costs. Their quicker installation time reduces labor expenses. Soldering takes longer and requires skilled labor, which can be more costly.

Soldering may offer a lower material cost for budget-conscious projects. Compression fittings can also save on labor expenses, making them more cost-effective in some cases.

Ease Of Use

Compression fittings have a significant advantage in terms of ease of use. They are user-friendly and do not require specialized skills. Even beginners can install them with minimal guidance, making them ideal for DIY projects.

Soldering requires practice and precision. The process involves handling a torch and molten solder, which can be intimidating for novices. Mistakes can lead to weak joints or leaks, requiring more time and effort to fix.

Compression fittings also allow for quick repairs. If a joint starts to leak, simply tightening the nut can often resolve the issue. Soldered joints require cutting and re-soldering to fix leaks, which is more time-consuming.

Compression fittings are the better option for those seeking a straightforward and hassle-free installation. They offer a user-friendly alternative to the more complex soldering process.

Which One To Choose?

Choosing between compression fitting and solder for plumbing can take time and effort. Both methods have their pros and cons. Knowing which one to pick can save you time and money. This guide will help you decide based on your needs.

Application Type

Different applications require different methods. Compression fittings are best for temporary or adjustable connections, small repairs, or adjustable installations. They work well with copper, plastic, and stainless steel pipes.

Soldering creates a permanent bond. It is ideal for long-term installations, such as copper pipes and high-pressure systems. Soldered joints are strong and last a long time.

Here is a quick comparison:

| Application | Compression Fitting | Solder |

|---|---|---|

| Temporary Connections | Yes | No |

| Permanent Connections | No | Yes |

| High Pressure | No | Yes |

Skill Level

Compression fittings are easy to use. Almost anyone can install them. All you need is a wrench. Just tighten the fitting, and you’re done—no special skills are required.

Soldering requires more skill. You need a torch, solder, and flux. You must also know how to heat the pipe and apply the solder. It takes practice to get it right, and mistakes can lead to leaks.

Here is a skill level comparison:

- Compression Fitting: Beginner-friendly

- Soldering: Requires training

Budget

Compression fittings can be more expensive per fitting, but they save money on tools and training. If you do small projects, this can be cheaper.

On the other hand, soldering may cost less per joint, but the initial investment in tools and materials can be significant. However, this method can save you money over many projects, making it a cost-effective choice in the long run.

Here is a budget comparison:

| Cost Factor | Compression Fitting | Solder |

|---|---|---|

| Initial Cost | Lower | Higher |

| Cost per Joint | Higher | Lower |

| Long-Term Cost | Variable | Lower |

Time Constraints

Compression fittings are fast to install. You need to tighten the fitting. This makes them great for quick repairs.

Soldering takes more time. You need to prepare the pipe, apply flux, and heat it. This process can take several minutes per joint.

Here is a time comparison:

- Compression Fitting: Quick installation

- Soldering: Time-consuming

Frequently Asked Questions

Are Compression Fittings Better Than Soldering?

Compression fittings are faster and easier to install, while soldering provides a more durable, leak-proof connection. Choose based on your project needs.

Do Professional Plumbers Use Compression Fittings?

Yes, professional plumbers use compression fittings. They offer reliable, leak-proof connections, are ideal for various plumbing applications, and are easy to install.

What Are The Disadvantages Of Compression Fittings?

Compression fittings can leak under high pressure. They require precise installation, and repeated disassembly weakens the connection. Therefore, they are not suitable for soft tubing materials.

When Would You Use A Compression Joint Instead Of A Soldered Joint?

Use a compression joint for quick, easy installation without special tools. Ideal for temporary fixes or areas needing frequent disassembly.

Conclusion

Choosing between compression fittings and solder depends on your specific needs. Both methods offer unique advantages. Compression fittings are quick and easy, ideal for DIY projects. Soldering provides a durable, long-lasting solution, perfect for professional plumbing. Evaluate your project requirements and skill level to make the best decision.